By 2045, nation to have over 100m such machines deployed across industries, with total value of some 10 trillion yuan

BEIJING — An evolution driven by data is quietly unfolding within China's robotics landscape, one that is expected to transform the fabric of daily life.

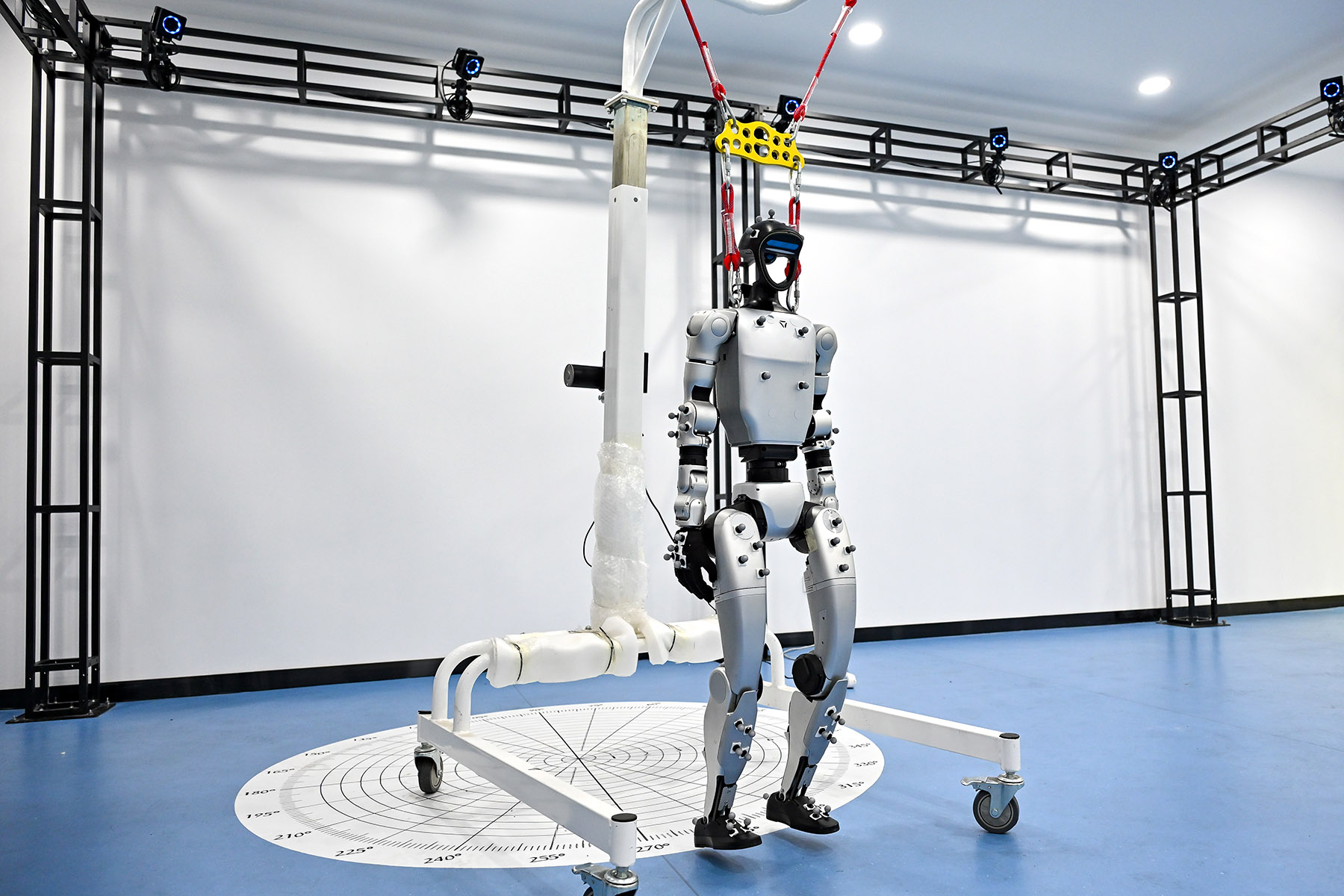

At a busy training facility in the western suburbs of Beijing, 1.66-meter-tall humanoid robots were using virtual reality and motion capture systems to learn practical skills like warehouse tasks, material sorting and product packaging.

This scene, far from a mere tech showcase, captured a critical evolution in China's robotics sector — the transition of humanoid robots from executing laboratory stunts to learning practical skills in "vocational schools".

The robots, which are named Kuavo — developed by Leju Robotics — are fast learners. They have already achieved success rates of over 95 percent in practical tasks such as returning empty crates, sorting materials, as well as weighing, packing and boxing wares.

READ MORE: China's AI industry thrives with over 5,300 enterprises

This pragmatic approach is key to unlocking these robots' effective use in real-world applications — from auto manufacturing to logistics — and accessing a trillion-dollar market.

A think tank report forecasts that by 2045, China will have over 100 million humanoid robots deployed across industries, creating a total market value of approximately 10 trillion yuan ($1.4 trillion).

Competing in this massive market, however, still faces technical hurdles. While viral videos of robots performing acrobatics or intricate dances have captivated the public over the past year, such a display of technical mastery obscures the underlying challenge of deploying robots in unstructured, unpredictable everyday settings.

To bridge the data shortage, Chinese robot makers are getting their machines into internships in automotive plants, warehouses, eldercare facilities and even a theater school.

"A robot becomes intelligent through repeated practice in different environments, much like a child needs to constantly practice learning how to walk," said the project's lead Wang Qiang.

Spanning over 10,000 square meters and capable of generating more than six million data entries annually, the newly inaugurated facility replicates 16 intricate scenarios across industrial, home, healthcare and 5G applications. This makes it not only the largest testing environment in China, but also one of the most comprehensive and realistic in the country.

By collecting increasing data from the training school, the robot developers can refine algorithms, enhance perception systems and improve decision-making capabilities.

A race is underway among China's major cities to position humanoid robots as the next key engine for economic growth. The priority for many local governments is attracting robotics startups and promising research labs with strong commercial potential to set up operations in their regions.

Donning VR headsets and holding controllers, hundreds of data collectors at a 4,000-square-meter facility of Shanghai startup AgiBot are manually teaching robots how to do chores like folding clothes, clearing tables, pouring tea and checkout operations.

This July, AgiBot and its partners livestreamed an unscripted, real-world stress test for their dual-armed, wheeled robots at a car parts factory in Mianyang, Sichuan province, for three uninterrupted hours.

Also in Mianyang, a robotic training ground kicked off in July as part of the region's strategy to build a competitive embodied artificial intelligence robotics cluster.

In September, another similar education facility started operating in Foshan, Guangdong province, hatched by a research institute affiliated with the Chinese Academy of Sciences. As part of its expansion, the institute has set the headquarters of its new general-purpose multimodal AI platform, Taichu, in Wuhan, Hubei province, and plans to build a new robotics training place there this year.

The inter-city rivalry is fueling faster innovation in robotics and this competitive dynamism does not hinder a unified national market.

The Beijing training ground, to be linked to facilities in eastern and central Chinese cities, is projected to generate 5,000 hours of data monthly.

Unitree Robotics, a prominent Chinese robotics firm known for its eye-catching robot demos, announced the open-sourcing of its robotic learning architecture recently. This move follows China's championing of open-source ecosystems in AI-generated large models, with the same strategy now being replicated in intelligent robotics.

ALSO READ: China showcases robotics might at robot conference

Unitree's AI engine allows humanoid robots to learn without repeatedly stumbling in the real world. Using a single snapshot and a handful of planned future motions, it can simulate and steer outcomes in real time.

Earlier this year, Shanghai-based robot maker Fourier unveiled N1, an open-source humanoid robot. Alibaba DAMO Academy soon followed by open-sourcing its self-developed vision-language-action model and a robot context protocol.

Also, AgiBot launched an open-source model GO-1. "Training a robot to pour water previously required collecting over 10,000 high-quality data samples," said Ren Guanghui, a researcher from AgiBot. "Our new open-source model will help cut that to only 1,000 pieces."

At a Shanghai tech meeting in August, Unitree CEO Wang Xingxing said some top universities have built many open-source algorithms on Unitree robots.

"The industry's progress is a collective effort, not the work of any single company or lab," Wang said.